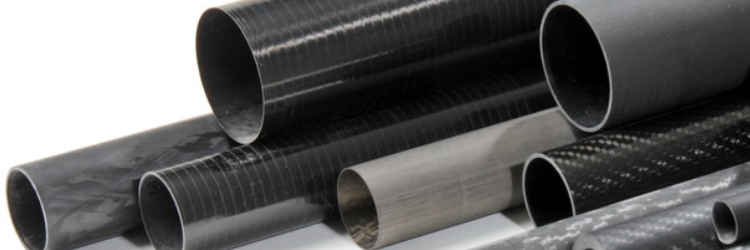

Carbon Fiber Tube Manufacturer

Hindustan Engineers is proud to offer carbon fiber tubes, a revolutionary material known for its exceptional properties that significantly outperform traditional steel and aluminium. These tubes boast a remarkable strength-to-weight ratio, making them 6-12 times stronger than steel while being significantly lighter (less than 1/4th the density). This unique combination of strength and lightweight characteristics makes them ideal for demanding applications across a wide range of industries.

Where it's Been Used

Hindustan Engineers’ carbon fiber tubes excel in diverse applications due to their exceptional strength-to-weight ratio, corrosion resistance, and fatigue resistance.

- Robotics & UAVs: Lightweight drone arms, landing gear, etc.

- Industrial Automation: Telescopic manipulators for precise movement.

- Metrology: High-precision measuring equipment due to dimensional stability.

- Photography & Surveying: Stable and portable tripods.

- High-Performance Vehicles: Drive axles for weight reduction and strength.

- Cleaning: Long, durable cleaning poles.

- Industrial Machinery: Strong, stiff, and fatigue-resistant components.

- Sports Goods: Golf shafts, fishing rods, and more.

- Boats & Yachts: High-performance masts for superior strength and stiffness.

Hindustan Engineers’ carbon fiber tubes boast exceptional properties that outperform traditional materials:

- Unparalleled Strength-to-Weight Ratio: 6-12 times stronger than steel yet remarkably lightweight (less than 1/4th the density).

- Superior Tensile Strength: Withstands high pulling forces without compromising integrity.

- Corrosion & Shock Resistance: Resists rust, degradation, and impact for long-lasting performance.

- High Toughness & Modulus: Delivers exceptional rigidity and dimensional stability under load.

- Fatigue Resistance: Maintains strength and durability even under repeated stress.

We manufacture high quality carbon fiber tubes using Roll wrapped and Filament winding process

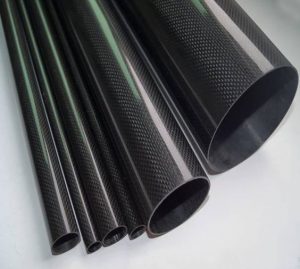

Roll Wrapped

Roll wrapped prepreg carbon fiber tubes are constructed using multiple wraps of twill and/or unidirectional fabrics.

- Ideal for small to medium diameter tubes (8mm – 100mm) and lengths up to 1.5 meters.

- Applications: Robotics, telescoping poles, rollers, UAV components.

- Fabric Options: 3K carbon fiber twill & plain weave.

- Finish Options: Glossy, Matte, or Sanded.

- Benefits: Highest bending stiffness and lowest weight for optimal performance in applications demanding rigidity and minimal weight.

Filament Winding

Filament winding is a composite manufacturing process in which continuous fibers or rovings are applied to a shape, known as a mandrel, to create a composite part.

- Suitable for a wider range of sizes, lengths, and finishes.

- Applications: Pressure vessels, drive shafts, and various industrial components.

- Benefits: Excellent for handling torsional stress due to the winding angle customisation.

If you need something you don’t see, just contact us and update what you’re looking for

Carbon fiber plates/sheets are multiple laminations of carbon in an epoxy matrix. The mechanical properties……

Vaccum Cleaning Poles

Carbon fiber roll wrapped telescopic vacuum Poles used for Gutter cleaning, commercial and residential vacuum …..

Telescopic Tube

For applications that require working at a distance, minimizing component weight is essential to improve maneuverability ……